Mimicking

Bone - Chemical and Physical Challenges

Sophie

C. Cox (WMG,

University of Warwick)

Abstract

It

is known that chemical and physical features of bone contribute to its

functionality, reactivity and mechanical performance. This article

presents a

summary of previously published studies conducted by the author with

the aim of

fabricating a synthetic structure, referred to as a scaffold, which

both

chemically and physically emulates the intricate structure of bone.

Novel work

aimed at improving the understanding of the synthesis of a ceramic

biomaterial,

namely hydroxyapatite, that is chemically similar to bone mineral is

discussed.

A case study involving the manufacture of porous scaffolds by 3D

printing is

also presented. In summary, this article highlights a number of

on-going

challenges that multidisciplinary tissue engineers aim to solve to get

one-step

closer to mimicking bone, which clinically could improve the quality of

life

for millions of people worldwide.

Keywords:

Bone

tissue engineering;

Scaffolds; Hydroxyapatite; Synthesis; Characterisation

Introduction

Bones

perform several vital

functions within the body, primarily structural support and protection

of

bodily organs. The ability of bone to self-repair and remodel to meet

varying

mechanical demands makes it a unique structural composite material (Chamay

and Tschantz 1972; You

et al.

2010).

Bone also serves as (a) an attachment

site for muscles to enable limb movement and joint mobility, (b) a

reservoir

for minerals (e.g. calcium and phosphorous), and (c) the primary site

for the

synthesis of blood cells.

The

capacity of bone to

function healthily can be affected by pathological conditions,

diseases, and it

is also well known that bone degenerates with age (Ritchie et

al. 2006).

Furthermore, the ability of bone to

self-repair is limited by what is known as the ‘critical size

defect’, defined

by Schmitz and Hollinger as “the smallest intraosseous wound in a

particular

bone and species of animal that will not heal spontaneously during the

lifetime

of the animal” (1986).

Major

alterations in bone

structure due to injury or disease can lead to discomfort and a reduced

quality

of life. Furthermore, defects outside of the limitations of natural

self-repair

may require surgical intervention, thus creating a demand for

appropriate

clinical strategies.

The

highly organised and

complex structure of bone, however, means this clinical need presents

an on-going

medical challenge. Traditionally bone grafts (BGs) and most commonly

autografts

– tissue harvested from another location in the patient’s

body – have been used

to fill or heal such defects. Despite being the ‘gold

standard’, there are

several disadvantages of autologous BGs, including painful harvesting

surgery,

limited supply, and long recovery times. These shortcomings have driven

the

biomedical research community to investigate alternative solutions that

incorporate the use of synthetic biomaterials.

Specifically,

an alternative

strategy to traditional approaches is to create a temporary surrogate

structure, which guides and encourages tissue regeneration. In order

for such a

strategy to be successful, it is necessary to combine expertise of

cells,

biochemical factors, and biomaterial science. This interdisciplinary

field of

research is known as tissue engineering and the structural component of

this

strategy is referred to as a ‘scaffold’.

Ideally,

a scaffold should

emulate the chemical and physical structure of the native tissue, thus

it is

crucial that an understanding of the properties that infer the

functionality of

bone is developed. Much attention has been given to calcium phosphate

(CaP)

based biomaterials since generally they are chemically similar to bone

mineral.

In particular, hydroxyapatite (Ca10(PO4)6(OH)2

- HA) has been shown to exhibit a comparable crystal structure (Posner

1969, Cazalbou et

al. 2004).

This chemical likeness and the natural

biological response that is elicited upon implantation is a key

advantage of HA

in comparison to other biomaterials commonly used in orthopaedic

applications,

such as metals (e.g. Ti6Al4V), polymers (e.g. HDPE) or bioglasses (e.g.

45S5). The

Food and Drug Association (FDA), a USA agency that protects public

health

through supervision and regulation, has extensive guidelines for the in-vivo use of HA in the form of, for

example, metallic implant coatings and void fillers.

This

material, despite its

promising features is known to exhibit poor resorbability and

reactivity under

physiological conditions compared to natural bone mineral due to its

high

stability (Cengiz et al.

2008).

Substitution of trace elements that

naturally occur in bone (for example Mg, Sr, Zn) and the use of

nanosized (10-9m)

HA (nHA) have been shown to enhance the solubility, reactivity and

response of

bone cells to this synthetic material in-vitro

and in-vivo (Webster et al.

2001; Leventouri 2006; Boanini et al.

2010).

It is, however, important to note,

that any changes to chemical composition must seek further FDA

approval, which

is a lengthy and costly process. Much effort has been focused on the

synthesis

of this bioceramic due to the potential applications of HA as a bone

replacement material (Elliott

1994; Raynaud et al.

2002; Bose and Saha 2003; Landi et al.

2008).

The majority of such studies, however,

are restricted to the preparation and structural investigation of HA

without an

evaluation of biological performance (Xue et al.

2006).

Lack of biological

testing is likely due to it being an expensive and time-consuming

process. In

addition, it may also be true, in some cases, that this is combined

with a lack

of appreciation of the effects of physicochemical alterations to the

biological

performance of HA.

Numerous

authors have

reported the fabrication of pure or composite HA scaffolds using a

variety of

techniques (Hutmacher

2000; Macchetta et

al. 2009).

In recent decades focus has been

directed to the use of additive layer manufacturing (ALM) systems to

produce

such constructs layer-by-layer since they can be user defined, which

inherently

improves reproducibility and enables the creation of patient-specific

products.

It is relatively common that commercially purchased HA is used as a

precursor

material and as such the motivation of such studies is narrowed to the

influence of physical attributes. That is despite the fact that the

reactivity

of bone mineral is largely determined by its composition and crystal

structure,

which in turn is determined by the synthesis method and reaction

conditions (Cazalbou et

al. 2004).

This

article presents an

overview of the author’s research to date while highlighting

other key works

within the field. The studies presented are focused on developing an

understanding of how the conditions used during aqueous precipitation

(AP) of

HA and 3D printing (3DP) influence critical scaffold properties.

Ultimately, the

aim of this article is to unearth chemical and physical challenges

involved in

mimicking bone and discuss the next steps of the author’s work as

well as the

field of biomaterials.

Chemical

Challenges

The

largest component of bone by weight

is the mineral phase (65 – 70wt%), which can be described as a

non-stoichiometric carbonated multi-substituted apatite that exhibits a

similar

crystal structure to HA. There

are numerous

conventional techniques that have been used to synthesise synthetic HA.

A

review of such methods is outside the remit of this article,

however

a

comprehensive overview is presented in the author’s thesis (Cox

2013).

This article

is focused on synthesising HA via aqueous precipitation (AP), which is

a

popular method due

to the use of relatively cheap raw materials and low temperatures

resulting in

minimal operating costs. AP reactions, however, cannot be deemed as

trivial due

to the simultaneous occurrence of crystal nucleation, growth, as well

as

coarsening and/or agglomeration. These underlying scientific mechanisms

are not

easy to differentiate and as a result reproducibility as well as the

control of

particle flocculation remain common factors for improvement (Narasaraju

and Phebe 1996,

Suchanek

and Yoshimura 1998,

Phillips et al. 2003).

The sensitivity

of phosphates and the need to fine tune the experimental conditions

(e.g. pH,

temperature) of AP reactions is reflected in the literature by the

ranging

phase purity, particle morphologies as well as sizes, crystallinity and

thermal

stability. Despite the shortcomings of AP methods, the potential to

produce HA

containing various ionic substitutions and its high scalability make it

an attractive

methodology, particularly for industrial scale production (Boanini et al.

2010).

The

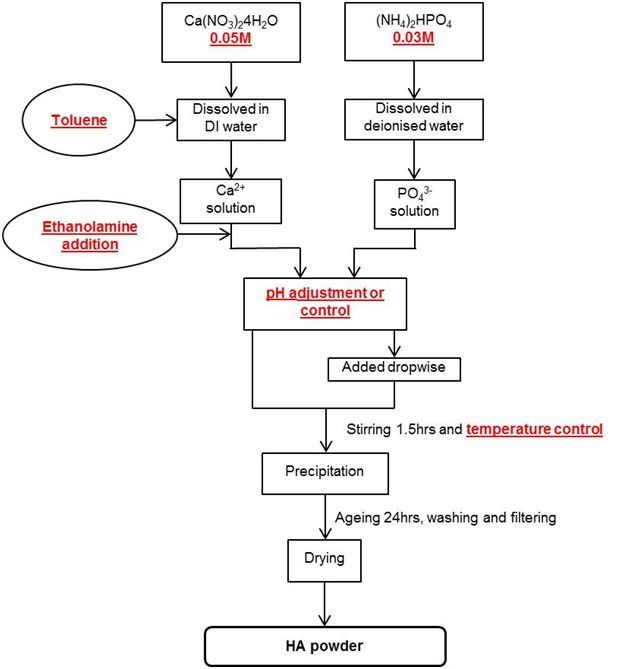

AP method used by the author to synthesise samples A – G (Table

1) is outlined in Figure 1, for full details please refer to the

referenced

publications.

Figure

1: Flowchart illustrating the aqueous precipitation method used by Cox et al. to synthesise hydroxyapatite with

varied conditions highlighted in red

In

spite of the widespread

use of AP methods and the range of reaction conditions reported in the

literature, few authors have systematically investigated the

relationship

between such conditions and biological performance. Novel work by Cox et al. showed through the use of in-vitro

assays utilising MC3T3

osteoblast precursor cells, derived from mice, that changing the pH,

temperature and solvent used during the AP of HA can significantly

affect the

degree of proliferation on such substrates (Cox

2013; Cox et al.

2014).

Table 1 summarises

the conditions that HA samples were precipitated under and results of

the

performed in-vitro assays.

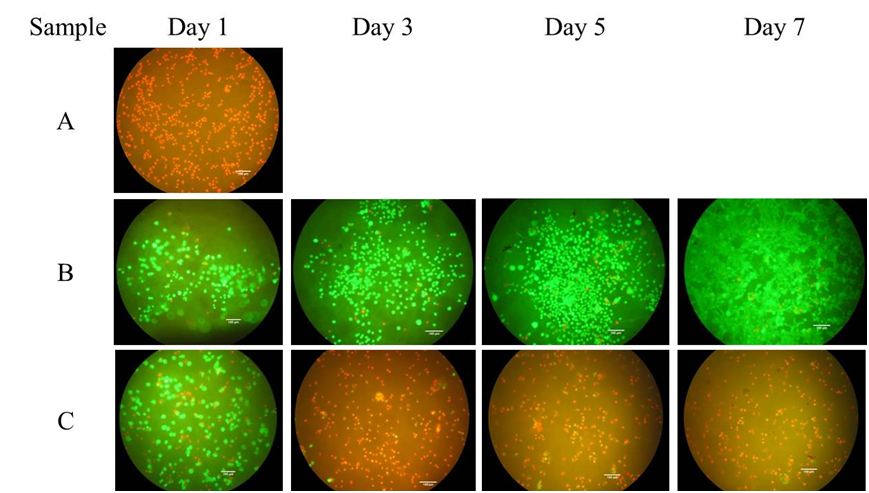

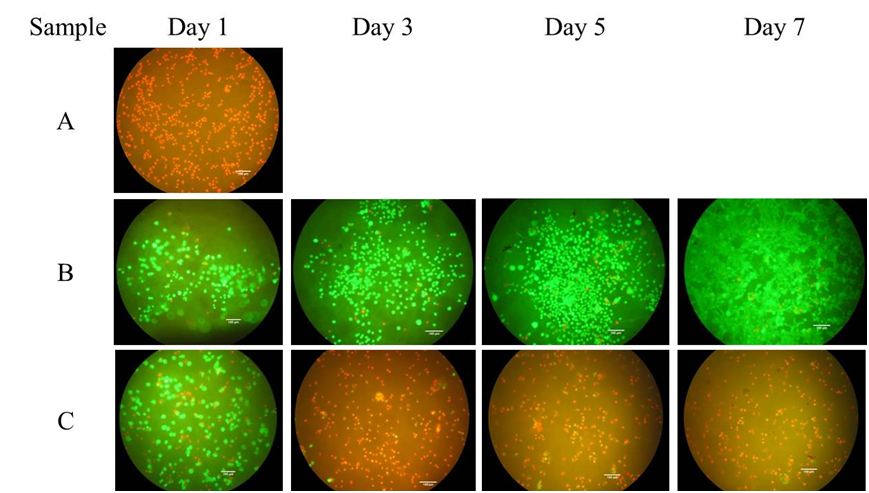

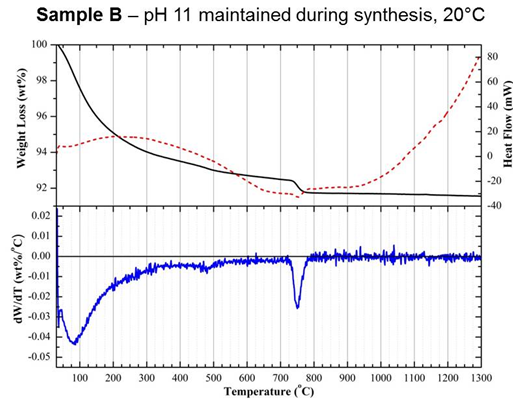

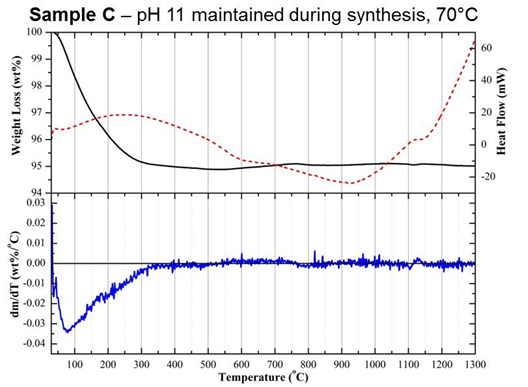

Fluorescence micrographs revealed that not maintaining the pH at 11

during

synthesis (Sample A) resulted in dead (red) cells after 1 day of

culture,

illustrating the critical importance of the value and control of this

parameter

(Figure 2). A comparison of samples B and C, prepared under the same pH

conditions but at 20 and 70°C, respectively, highlights that

fine-tuning of AP

reactions is vital to ensure a non-cytotoxic HA substrate is produced

(Figure

2). Both of these differences in biological outcomes were attributed to

subtle

changes in physicochemical properties, which were identified through

the

combined use of a range of material characterisation methods, including

surface

area analysis, zeta potential, as well as simultaneous differential

thermal

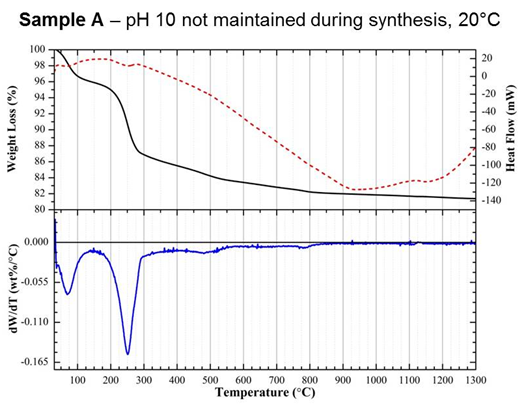

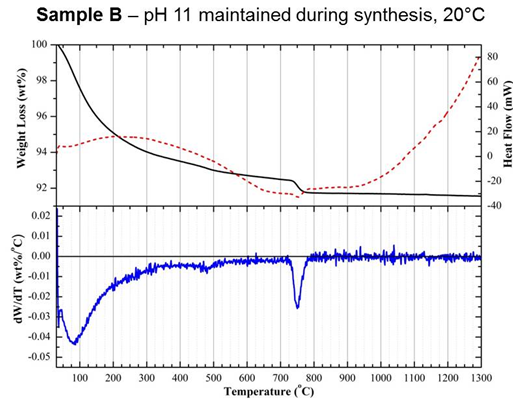

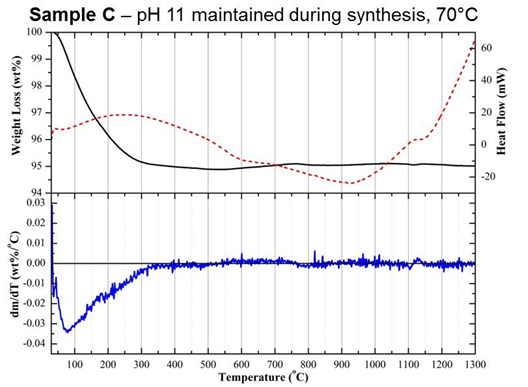

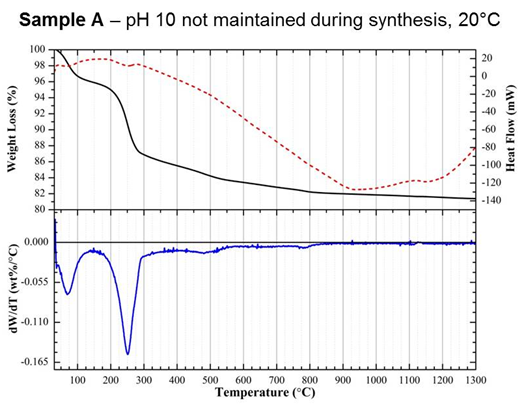

analysis (DTA) and thermogravimetry (TGA). In particular,

differentiation of

TGA curves (DTG) collected up to 1300°C

revealed

a significant change in the rate of weight loss for sample A between

200 and

300°C,

which

was not seen in samples B or C (Figure 3). Weight loss within this

region was

attributed to the dehydration of an acidic CaP phase, dicalcium

phosphate

dihydrate (CaHPO4·2H2O), otherwise known

as brushite.

Samples A and C were both shown to exhibit positive zeta potentials

compared

with the varying degrees of negative values measured for samples that

were

shown to be non-cytotoxic using a dead/live assay, such as sample B

(Table

1). These positive values were attributed to the presence of secondary

acidic

CaP phosphates, which are proposed to have been released during culture

resulting in cell death.

Figure

2: Fluorescence

micrographs from a dead/live assay illustrating the critical influence

of pH and temperature on the viability of MC3T3 cells from 1 to 7 days

of culture (red = dead; green = live) (Cox

2013)

In

addition to pH and

temperature, the author has also previously investigated the effect of

changing

the solvent in which the HA crystals are precipitated. A proliferation

rate of

194% between 1 and 7 days of culture of MC3T3 cells seeded on HA

substrates

precipitated in a mixed Toluene and deionised (DI) water solvent system

was

calculated from results of an in-vitro

MTT assay (Table 1). This was compared with a 82% increase in cell

number on HA

prepared in the same manner but in a pure DI water system (Cox

2013).

This significant

increase in cell number was attributed to a reduction in the dielectric

constant of the solvent system, as a result of using Toluene instead of

polarised DI water, reducing the degree of crystallinity and surface

charge as

well as increasing the surface area of precipitated HA particles (Table

1).

The

hexagonal crystal

structure of HA enables partial or total replacement of ions, and in

bone

apatite numerous biologically relevant ionic substitutions occur.

Divalent

cations (e.g. Mg2+) and monovalent cations (e.g. K+)

can

substitute for Ca2+, and anions such as fluoride (F-)

or

chloride (Cl-) may substitute for OH- groups.

Furthermore, some ions such as carbonates can substitute for OH-,

PO43-

or

both, which are referred to as A, B and AB type substitutions,

respectively (Cazalbou et

al. 2004).

Therefore, an

appropriate formula for bone apatite can be expressed as (Ca, X)10(PO4,

CO3, Y)6(OH, Z)2 with X as

substituting cations,

and Y and Z being the substituting anions, with the indices 10, 6 and 2

changing according to the degree of stoichiometry (Weiner

and Wagner 1998).

In an effort to

emulate the higher reactivity of bone mineral, a number of biomedical

groups

concerned with CaPs have investigated substituting naturally occurring

ions

into synthetic HA (Capuccini et

al. 2008; Landi et al.

2008; Bohner

2009).

A number of reports have confirmed

that substitution of Sr, Mg or Zn can influence the crystallinity,

solubility,

surface charge, and physiological dissolution rate of synthetic

CaPs (Boanini et al.

2010).

Each of these divalent cations are known

to play important roles in the biological responses of bone cells.

Despite the

synthesis of substituted HA attracting much interest, to the best of

the

author’s knowledge Sr, Mg or Zn substituted HA prepared under the

same

experimental conditions has not previously been reported. As

highlighted above changes

in reaction conditions, such as pH, can greatly influence the physical,

chemical, and crystal structure of precipitated apatite, which makes it

difficult to determine the sole influence of substituents when

comparing

literature since variations in synthesis conditions, particularly pH

and

temperature, are common. Hence it is proposed that a comparison of HA

doped

with Sr, Mg or Zn prepared under the same experimental conditions is a

more

accurate assessment of the individual influence of these cations. Such

a study

was previously published by the author and concluded that doping HA

with 10mol%

Mg or 2mol% Zn enhanced the degree of cellular proliferation over a 7

day

period compared with pure HA (Cox et al.

2014).

The significantly

higher proliferative rates calculated for Mg- and Zn-HA were attributed

to the

altered composition as a result of incorporation of dopants into the

lattice

structure and increased surface areas of particles (Table 1).

In

summary, the author’s previously

published work that is discussed provides evidence that cell

proliferation may

be positively influenced by maintaining a pH level of 11 during

synthesis,

precipitating HA in a mixed Toluene and DI water system, and doping HA

with 10mol%

Mg or 2mol% Zn. Generally, the selection of a synthesis method and

conditions

to produce HA cannot be deemed a trivial step in addressing the

chemical

challenge of mimicking bone mineral (Cox et al.

2014).

In the words of

Drouet, ‘all that glitters is not gold… all that is white

is not apatite

either’ (Drouet

2013).

Physical

Challenges

Bone

exhibits a

heterogeneous and anisotropic structure that comprises different

components at

a range of length scales. Macroscopically bone is distinguished into

cortical,

otherwise known as compact, and cancellous, also referred to as

trabecular or

spongy bone. Cortical and cancellous bone can be easily distinguished

by their

degree of porosity: 4 - 28%, and 40 - 95%, respectively (Gibson

1985).

The denser

structure of cortical bone forms the outer region of all types of bone,

the

diaphysis (shaft) of long bones, and flat bones providing protection

and

support for the inner regions. In contrast, cancellous bone exhibits

macro-sized pores, filled with bone marrow, which is found in the

centre of all

bones. The intricate organisation of bone confers its functionality,

however,

for biomedical scientists this precise structural arrangement presents

a number

of challenges when trying to produce a scaffold that mimics its

porosity and

pore sizes, interconnectivity, topography, and mechanical strength.

Broadly,

scaffold

fabrication methods can be grouped as conventional or ALM techniques.

In

general, the fabrication method should adhere to: (1) does not

adversely affect

the chemical composition, mechanical properties or cytocompatibility of

the

material, (2) the technique should be accurate so pore size and

morphology can

be defined by the user, and (3) minimal variation in physical form

between

batches (i.e. consistency) (Leong et al.

2003).

Scaffolds of complex shapes with a

range of process dependent porosities from 30 - 98% can be produced by

conventional techniques, such as freeze-drying or solvent casting. In

contrast

to ALM technologies, conventional processes require small capital input

but

typically scaffolds made using these techniques perform poorly

mechanically in

comparison to native bone. Reproducibility is another issue associated

with

these methods due to the inability to precisely control scaffold

characteristics, such as pore size, pore interconnectivity and spatial

distribution of pores. Conventionally fabricated constructs commonly

fail to

meet the demand to create highly porous networks necessary for cell

growth, flow

of nutrients and metabolic waste (Hutmacher

2000).

Often, these techniques also require

the use of organic solvents, such as chloroform, which if any residues

remain

in the structure may be toxic and/or carcinogenic to cells.

There

are a variety of ALM

systems based on computer aided design (CAD) and manufacture (CAM).

Such

techniques were first used for biomedical applications in the 1990s and

can be

categorised into three groups: (1) laser (e.g. stereolithography), (2)

print or

‘ink’ (e.g. 3D printing) and (3) nozzle systems (e.g. fused

deposition

modelling). A comprehensive review of ALM techniques for the

fabrication of

bone scaffolds is presented by Hollister (2005).

Generally, ALM techniques can be used

to accurately fabricate parts of complex designs and near net shape

processing

minimises material waste. Furthermore, data generated from a scan (CT

or MRI)

of the patient may also be used as a template allowing the manufacture

of

customised implants, meaning desired levels of hierarchical complexity

can be

built into the part, which is advantageous when trying to mimic the

intricate

physical structure of bone. Due to the higher level of structural

control it is

possible to produce scaffolds via ALM techniques with superior

mechanical

properties in comparison to conventionally manufactured

counterparts (Cox

2013).

The

author’s work is focused

on the use of an ALM technique called 3D printing (3DP), which is a

powder

based technology that involves layers of the stock material being

bonded

together by an appropriate liquid binder that is propelled onto the

powder bed

from a printer head. This process is much the same as what happens in

an

ink-jet printer but it is repeated layer-by-layer until the final 3D

part is formed.

Any unbound material may act as a support during the building process,

however,

this material must be removed after printing. In addition to exhibiting

the

inherent advantages of ALM systems, such as geometry control, 3DP

creates parts

with a rough surface. This is particularly advantageous for a bone

tissue

scaffold since the pits and troughs provide fixation points for cells

to adhere

to when it is implanted. Furthermore, the imperfect packing of powder

particles

results in small micropores within the solid structure, which may

facilitate

cell in-growth, vascularisation, and fluid flow.

For

the 3DP process to work,

it is essential that the powdered stock material has an ability to flow

to

enable adequate recoating of the part by the counter-rotating roller

during

layer-based manufacture. Particle size, morphology, and density have

been

reported to be critical factors in determining powder flowability (Butscher et

al. 2012).

A high level of flowability

contributes towards an improvement in the resolution of the final part

and vice

versa. However, if the flowability is too high the powder bed can

become

unstable. Wettability of the powder particles by the binder solution is

another

crucial factor as it influences both resolution and mechanical strength

of the

3D printed part. There are a number of parameters that influence powder

wetting,

including binder viscosity, topography of the powder bed surface (which

itself

is dependent on particle shape and size), and any chemical reactions

between

the binder and powder (Sachs et al.

1993).

Numerous

authors have

reported the fabrication of porous scaffolds by 3DP (Bose et al.

2013, Travitzky et

al. 2014).

Pure CaP powders,

for example α- and β-tricalcium phosphate (TCP) (Butscher et

al. 2012),

tetracalcium phosphate (Khalyfa et al.

2007),

and HA (Roy et al.

2003)

as well as composites of CaPs mixed

with organic polymers, such as poly(L-lactide-co-glycolide)-copolymer

(PLGA) (Roy et al.

2003),

have been utilised as stock materials.

Material combinations that require the use of organic solvents as a

binder, for

example PLGA and β-TCP binded with chloroform (Roy et al.

2003),

have an inherent disadvantage as

complete removal of the solvent is rather difficult due to the inherent

porosity of 3D printed structures.

The

feasibility of

fabricating 3D porous scaffolds from powder compositions of HA and

polyvinyl

alcohol (PVOH), suitable for use as a component of the tissue

engineering

strategy has been reported by the author (Cox

2013).

In short, to

manufacture constructs purchased PVOH and HA powders were mixed

together,

compacted into the powder bed of a ZPrinter 310 (ZCorp, USA) and bound

together

using a commercially available binder (Zb90, ZCorp, USA) using a user

defined

layer thickness of 0.1mm. Post-printing, scaffolds were left to dry for

1hr

before removing from the build bed, de-powdered using compressed air,

dried in

either a furnace or vacuum oven at 60°C

for either 2 or 6hrs, and sintered at 1300°C.

This

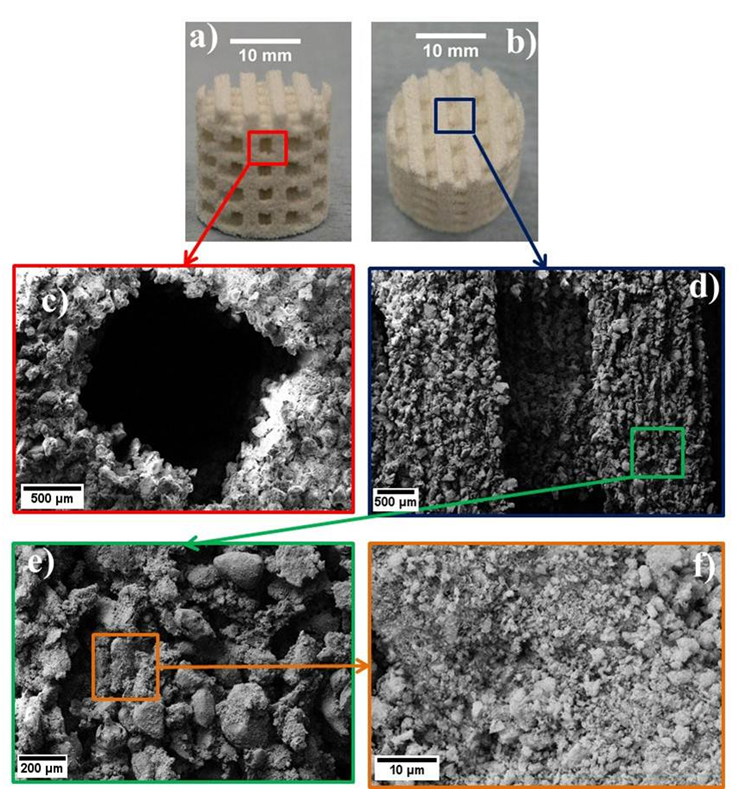

study highlighted the potential of 3DP to produce constructs that

exhibit key

structural criteria, such as surface roughness and porosity (Figure 4),

which

are known to be vital in determining the success of bone tissue

scaffolds.

Figures 4c and d illustrate that designed pore channels and struts were

accurately reproduced, this is important since the dimensions of these

features

were selected to enable cell migration and vascularisation. It is also

significant that topographical features from the mm (the designed

pores) to µm (surface

topography) are present, since a range of features are required for

different

biochemical effects/functions. For example, protein interactions

benefit from

micron sized features, cellular development is facilitated by pores

1-20µm,

bone in growth is improved by topographical pores 100-1000µm and

implant

functionality enhanced by pores >1000µm in size (Sanchez-Salcedo

et al.2008).

Figure

4: 3D printed scaffolds manufactured from 50HA:50PVOH powders

a)

Side view b) Top view, c) Designed pore channel, d) Scaffold strut, e)

and f)

Topography of scaffold surface (Cox

2013)

Characterisation

of powder flowability,

assessed using a funnel flow method, strongly correlated with observed

printability and can be deemed a vital prerequisite property since it

influenced recoating of the build bed, which ultimately determined

several

critical physical criteria such as mechanical strength, microstructure,

and

porosity. Scaffolds produced from less flowable precursors (i.e.

60HA:40PVOH)

were shown to be substantially weaker in compression and this was

attributed to

insufficient bonding between layers.Characterisation of green bodies

(i.e.

unsintered scaffolds) provided valuable information that facilitated an

understanding of the shrinkage behaviour observed as a result of

sintering to

1300°C.

Significant differences in the size of micropores were observed between

green

scaffolds printed along the X and Y-axes, which resulted in variation

of

mechanical strength, and influenced the effectiveness of the removal of

degradation products of PVOH during sintering. Simply the more voids,

or pores,

within the structure the weaker it is. Drying of green bodies after

printing

was shown to improve the compressive strength of scaffolds by up to

350%; this

was attributed to the shrinkage of micropores. Compression tests,

performed on

a 5800R 100kN static tester (Instron, UK) with 1kN load cell at a cross

head

speed of 10mm/min, also highlighted that interlayer bonding was

critical to bulk

strength and when parts were loaded perpendicular to the direction of

printing

(i.e. parallel to the boundaries of interlayer bonding) catastrophic

failure (i.e.

no or little plastic deformation) occurred. Highlighting that printing

direction is a critical consideration to implant design. A maximum

average

compressive strength of 0.88±0.02MPa was exhibited by 50wt% HA

green parts

printed along the Y-axis and dried for 6hrs in a vacuum oven at 60°C,

which is above the lower

value of 0.15MPa reported for cancellous bone (Cox

2013).

Conclusions

Bone

exhibits a highly

intricate physical structure and complex chemical composition, which

presents

the multidisciplinary field of tissue engineering with a number of

challenges

when trying to produce synthetic scaffolds that emulate this remarkable

composite. HA is a promising biomaterial for use in strategies to

replace bone

but our current understanding of this deceptive ceramic is not yet

complete as

highlighted by the author’s previous work, which is discussed in

this article. The

results of the synthesis studies referred to strongly advocate that pH

should

be maintained at 11 during preparation to ensure that a non-cytotoxic

precipitate is formed. Furthermore, the potential advantages of using

other

solvent systems to water was highlighted by the promising cell studies

conducted on HA synthesised in a mixed Toluene and water system.

Overall, the

author’s work in this area to date suggests that synthesis

conditions must be

carefully considered since they may have significant effects on cell

proliferation in-vitro.

The

3D printed scaffolds

illustrated in this article exhibit promising features for use in bone

tissue

engineering; rough topography for cell adhesion, compressive strength

values

comparable to cancellous bone, and an accurate replication of a user

defined

interconnected porous structure. Experimental work highlighted the

importance

of precursor characterisation and the advantages of printing along the

same

axis to part loading; in this case the Y-axis, as well as drying the

parts in a

vacuum oven for 6 hrs.

When

considering the major

advantage of ALM techniques to produce bone tissue scaffolds; the

ability to physically

tailor the construct, why should this idea not be combined with a

chemically

tailored stock material? The major shortcoming of the presented

research is the

challenges that the presented studies address have been achieved by

focusing

individually on either chemical or physical features. When looking at

the

author’s work as a whole it demonstrates the importance of

investigating

processing conditions so that techniques may be better understood and

ultimately this may translate to improved patient outcomes. Overall,

the

results presented are the foundation of further work, which is being

conducted

to combine the outcomes of the aqueous precipitation and 3DP studies.

In

particular, scale up the reported HA synthesis method is being explored

so that

an adequate amount of enhanced powder may be produced to use in the 3DP

process. If this is achieved, it will enable a new dimension of

tailoring but

while there are separate chemical and physical challenges, some of

which are

discussed here, there are certainly still many more difficulties to be

unearthed in an attempt to catch up with evolution’s efforts. In

conclusion,

the research presented highlights the importance of multidisciplinary

collaborations

within the biomedical field, which may enable the next generation of

customised

implants to be created.

Acknowledgements

The

author would like to

acknowledge the financial support of the Chancellor’s Scholarship

and the

Institute of Advanced Study both at the University of Warwick. Dr Kajal

K. Mallick,

who is sadly no longer with us, is also acknowledged for his

involvement in the

reported research.

References

Boanini, E., M. Gazzano and

A. Bigi (2010).

"Ionic substitutions in calcium phosphates synthesized at low

temperature." Acta Biomaterialia 6(6):

1882-1894.

Bohner,

M. (2009). "Silicon-substituted calcium phosphates–a critical

view."

Biomaterials 30(32): 6403-6406.

Bose, S. and

S. K. Saha (2003). "Synthesis and characterization of hydroxyapatite

nanopowders by emulsion technique." Chemistry of Materials 15(23):

4464-4469.

Bose,

S., S. Vahabzadeh and A. Bandyopadhyay (2013). "Bone tissue engineering

using 3D printing." Materials Today 16(12):

496-504.

Butscher,

A., M. Bohner, C. Roth, A. Ernstberger, R. Heuberger, N. Doebelin, P.

R. von

Rohr and R. Muller (2012). "Printability of calcium phosphate powders

for

three-dimensional printing of tissue engineering scaffolds." Acta

Biomaterialia 8(1): 373-385.

Capuccini,

C., P. Torricelli, F. Sima, E. Boanini, C. Ristoscu, B. Bracci, G.

Socol, M.

Fini, I. Mihailescu and A. Bigi (2008). "Strontium-substituted

hydroxyapatite coatings synthesized by pulsed-laser deposition: in

vitro

osteoblast and osteoclast response." Acta Biomaterialia 4(6):

1885-1893.

Cazalbou,

S., C. Combes, D. Eichert and C. Rey (2004). "Adaptative

physico-chemistry

of bio-related calcium phosphates." Journal of Materials Chemistry 14(14): 2148-2153.

Cengiz,

B., Y. Gokce, N. Yildiz, Z. Aktas and A. Calimli (2008). "Synthesis and

characterization of hydroxyapatite nanoparticles." Colloids and

Surfaces

a-Physicochemical and Engineering Aspects 322(1-3):

29-33.

Chamay,

A. and P. Tschantz (1972). "Mechanical Influences in Bone Remodeling -

Experimental Research on Wolffs Law." Journal of Biomechanics 5(2): 173-&.

Cox,

S. C. (2013). Synthesis and 3D printing of hydroxyapatite scaffolds for

applications in bone tissue engineering, University of Warwick.

Cox, S. C.,

P. Jamshidi, L. M. Grover and K. K. Mallick (2014). "Low temperature

aqueous precipitation of needle-like nanophase hydroxyapatite." Journal

of

Materials Science: Materials in Medicine 25(1):

37-46.

Cox,

S. C., P. Jamshidi, L. M. Grover and K. K. Mallick (2014). "Preparation

and characterisation of nanophase Sr, Mg, and Zn substituted

hydroxyapatite by

aqueous precipitation." Materials Science and Engineering: C 35: 106-114.

Cox,

S. C., R. I. Walton and K. K. Mallick (2014). "Comparison of Techniques

for the Synthesis of Hydroxyapatite."

Drouet,

C. (2013). "Apatite formation: why it may not work as planned, and how

to

conclusively identify apatite compounds." BioMed research international

2013.

Elliott,

J. C. (1994). Structure and chemistry of the apatites and other calcium

orthophosphates, Elsevier Amsterdam.

Gibson,

L. J. (1985). "The mechanical behaviour of cancellous bone." Journal

of Biomechanics 18(5): 317-328.

Hollister,

S. J. (2005). "Porous scaffold design for tissue engineering." Nature

Materials 4(7): 518-524.

Hutmacher,

D. W. (2000). "Scaffolds in tissue engineering bone and cartilage."

Biomaterials 21(24): 2529-2543.

Khalyfa,

A., S. Vogt, J. Weisser, G. Grimm, A. Rechtenbach, W. Meyer and M.

Schnabelrauch (2007). "Development of a new calcium phosphate

powder-binder system for the 3D printing of patient specific implants."

Journal of Materials Science-Materials in Medicine 18(5):

909-916.

Landi,

E., G. Logroscino, L. Proietti, A. Tampieri, M. Sandri and S. Sprio

(2008).

"Biomimetic Mg-substituted hydroxyapatite: from synthesis to in vivo

behaviour." Journal of Materials Science: Materials in Medicine 19(1): 239-247.

Landi,

E., G. Logroscino, L. Proietti, A. Tampieri, M. Sandri and S. Sprio

(2008).

"Biomimetic Mg-substituted hydroxyapatite: from synthesis to in vivo

behaviour." Journal of Materials Science-Materials in Medicine 19(1): 239-247.

Leong,

K. F., C. M. Cheah and C. K. Chua (2003). "Solid freeform fabrication

of

three-dimensional scaffolds for engineering replacement tissues and

organs." Biomaterials 24(13):

2363-2378.

Leventouri,

T. (2006). "Synthetic and biological hydroxyapatites: Crystal structure

questions." Biomaterials 27(18):

3339-3342.

Macchetta,

A., I. G. Turner and C. R. Bowen (2009). "Fabrication of HA/TCP

scaffolds

with a graded and porous structure using a camphene-based

freeze-casting

method." Acta Biomaterialia 5(4):

1319-1327.

Narasaraju,

T. S. B. and D. E. Phebe (1996). "Some physico-chemical aspects of

hydroxylapatite." Journal of Materials Science 31(1):

1-21.

Phillips,

M. J., J. A. Darr, Z. B. Luklinska and I. Rehman (2003). "Synthesis and

characterization of nano-biomaterials with potential osteological

applications." Journal of Materials Science-Materials in Medicine 14(10): 875-882.

Posner,

A. S. (1969). "Crystal chemistry of bone mineral." Physiol Rev 49(4): 760-792.

Raynaud,

S., E. Champion, D. Bernache-Assollant and P. Thomas (2002). "Calcium

phosphate apatites with variable Ca/P atomic ratio I. Synthesis,

characterisation and thermal stability of powders." Biomaterials 23(4): 1065-1072.

Ritchie,

R. O., J. W. Ager and G. Balooch (2006). "Fracture, aging, and disease

in

bone." Journal of Materials Research 21(8):

1878-1892.

Roy,

T. D., J. L. Simon, J. L. Ricci, E. D. Rekow, V. P. Thompson and J. R.

Parsons

(2003). "Performance of degradable composite bone repair products made

via

three-dimensional fabrication techniques." Journal of Biomedical

Materials

Research Part A 66A(2): 283-291.

Roy,

T. D., J. L. Simon, J. L. Ricci, E. D. Rekow, V. P. Thompson and J. R.

Parsons

(2003). "Performance of hydroxyapatite bone repair scaffolds created

via

three-dimensional fabrication techniques." Journal of Biomedical

Materials

Research Part A 67A(4): 1228-1237.

Sachs,

E., M. Cima, J. Cornie, D. Brancazio, J. Bredt, A. Curodeau, T. Fan, S.

Khanuja, A. Lauder, J. Lee and S. Michaels (1993). "Three-Dimensional

Printing: The Physics and Implications of Additive Manufacturing." CIRP

Annals - Manufacturing Technology 42(1):

257-260.

Sanchez-Salcedo,

S., D. Arcos and M. Vallet-Regi (2008). "Upgrading calcium phosphate

scaffolds for tissue engineering applications." Progress in Bioceramics

377: 19-42.

Schmitz,

J. P. and J. O. Hollinger (1986). "The Critical Size Defect as an

Experimental-Model for Craniomandibulofacial Nonunions." Clinical

Orthopaedics and Related Research(205): 299-308.

Suchanek,

W. and M. Yoshimura (1998). "Processing and properties of

hydroxyapatite-based biomaterials for use as hard tissue replacement

implants." Journal of Materials Research 13(1): 94-117.

Travitzky,

N., A. Bonet, B. Dermeik, T. Fey, I. Filbert‐Demut,

L. Schlier, T. Schlordt and P. Greil (2014). "Additive Manufacturing of

Ceramic‐Based Materials." Advanced

Engineering Materials.

Webster,

T. J., C. Ergun, R. H. Doremus, R. W. Siegel and R. Bizios (2001).

"Enhanced osteoclast-like cell functions on nanophase ceramics."

Biomaterials 22(11): 1327-1333.

Weiner,

S. and H. D. Wagner (1998). "The material bone: Structure mechanical

function relations." Annual Review of Materials Science 28:

271-298.

Xue,

W., J. L. Moore, H. L. Hosick, S. Bose, A. Bandyopadhyay, W. Lu, K.

Cheung and

K. D. Luk (2006). "Osteoprecursor cell response to strontium‐containing

hydroxyapatite ceramics." Journal of Biomedical Materials Research Part

A 79(4): 804-814.

You,

L. D., J. H. Chen, C. Liu and C. A. Simmons (2010). "Boning up on

Wolff's

Law: Mechanical regulation of the cells that make and maintain bone."

Journal of Biomechanics 43(1):

108-118.