Multi-objective Production Planning for a Flexible Manufacturing System based on NSBBO Method

DOI:

https://doi.org/10.31273/eirj.v7i1.288Keywords:

FMS, flexible manufacturing system, production system automation, production system planning, production scheduling, NSBBO, simulation, BBO, biogeography-based optimisationAbstract

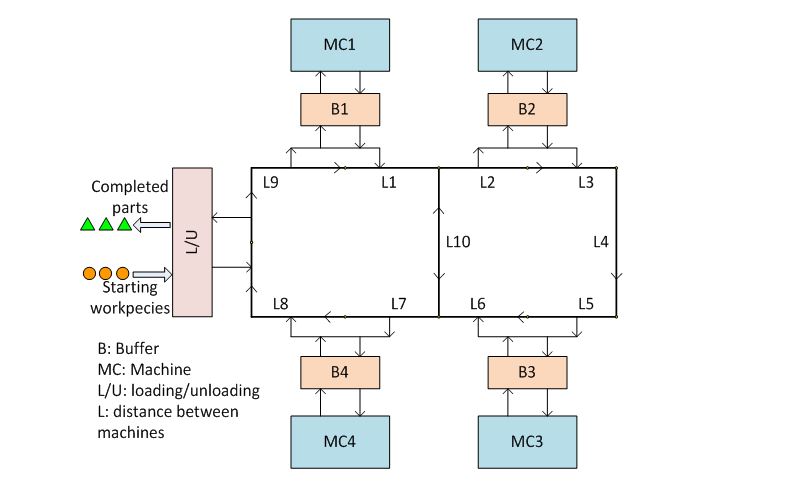

The dramatic expansion in the global manufacturing market has created a demand for small and medium enterprise (SME) to apply the advanced manufacturing technology (AMT). The flexible manufacturing system (FMS) is considered as a highly competitive manufacturing strategy to ensure the success of the enterprises in the developing countries. The implementation of FMS, however, is an intractable task that requires complete integration of numerous components from various vendors. This paper presents a multi-objective production planning model for selecting the most suitable combination of machines and operations in machining processes to simultaneously minimize the system unbalance, makespan (MK) and total flow time. The proposed model considered the capacity of machines, tool magazines, batch sizes, processing time and the time taken to transport machining parts. Moreover, it also considered the different allocation of each part of batch into various machines. The principle of biogeography-based optimization (BBO) is adapted to explore the possibilities of attaining feasible solutions for a formulated problem. The most appropriate solutions in selecting the machine and operation allocation were determined based on non-dominated sorting BBO procedure (NSBBO) and validated by FlexSim simulation environment. The obtained results highlighted the practical applicability in the implementation of FMS.

Downloads

Downloads

Published

Issue

Section

License

Copyright (c) 2019 Nguyen Huu Tho

This work is licensed under a Creative Commons Attribution 4.0 International License.

Authors who publish with this journal agree to the following terms:

Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License (CC-BY), which permits use and redistribution of the work provided that the original author and source are credited, a link to the license is included, and an indication of changes which were made. Third-party users may not apply legal terms or technological measures to the published article which legally restrict others from doing anything the license permits.

If accepted for publication authors’ work will be made open access and distributed under a Creative Commons Attribution (CC-BY) license unless previously agreed with Exchanges’ Editor-in-Chief prior to submission.

Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgement of its initial publication in this journal.

Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work. (see: The Effect of Open Access)